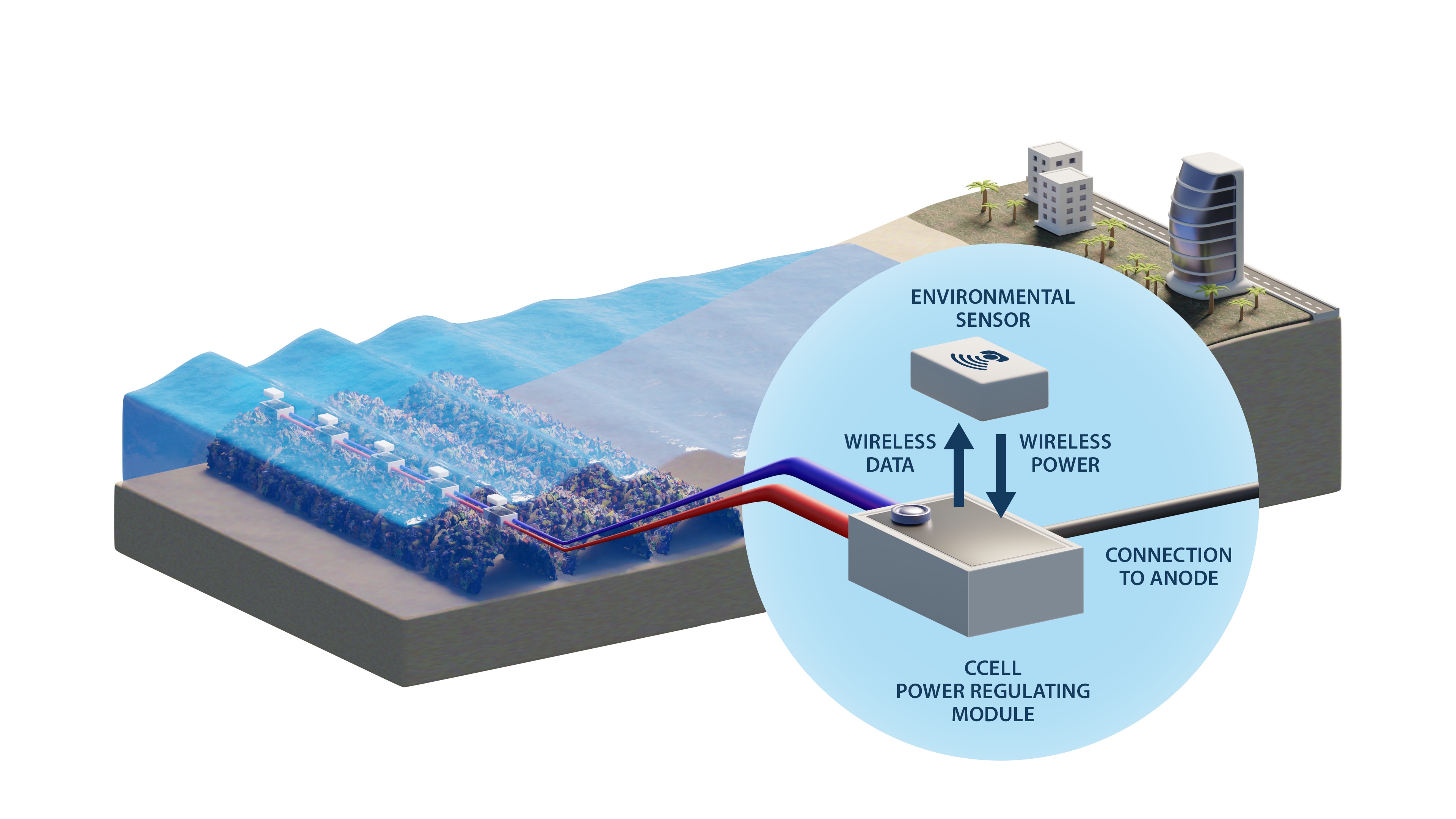

CCell are at the forefront of developing technologies which enable our marine environments to be measured, analysed, and protected. We design and install digitised living reefs that protect coastlines from erosion, restore near-shore marine habitats, and listen to our oceans.

The world is experiencing an unprecedented loss of coastlines and marine biodiversity. Our marine environment and its ecosystems have a profound impact on the planet, yet we know precious little about how our oceans are changing. We are developing techniques to quantify the impact of human activities on marine biodiversity, coastal formations and global warming. We then install infrastructure to help her recover.

Advanced simulations of waves, currents, severe storm, and coastal morphology.

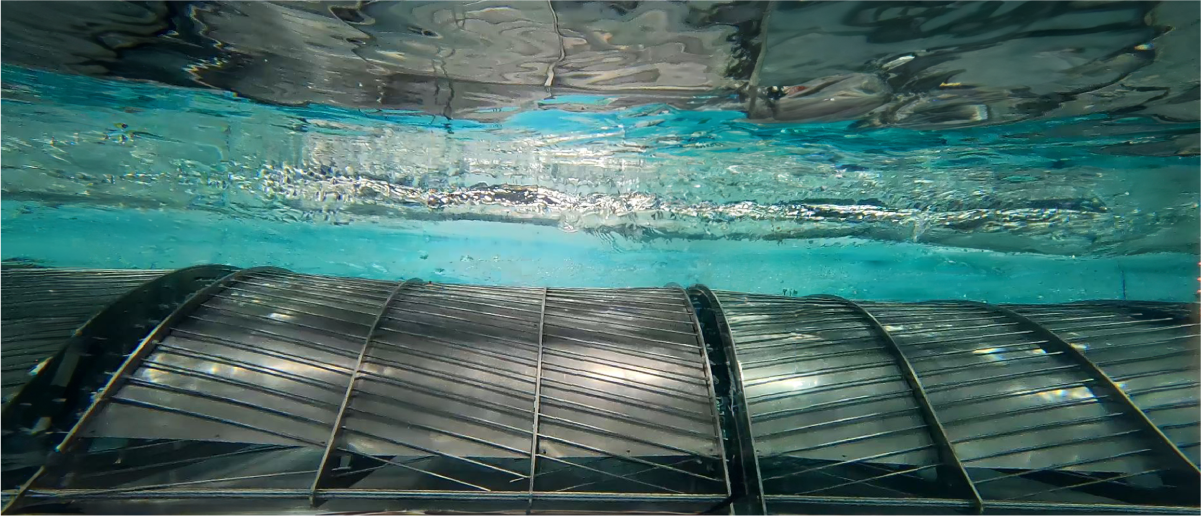

Nature based reefs that provide long-term stability for beaches and clifts.

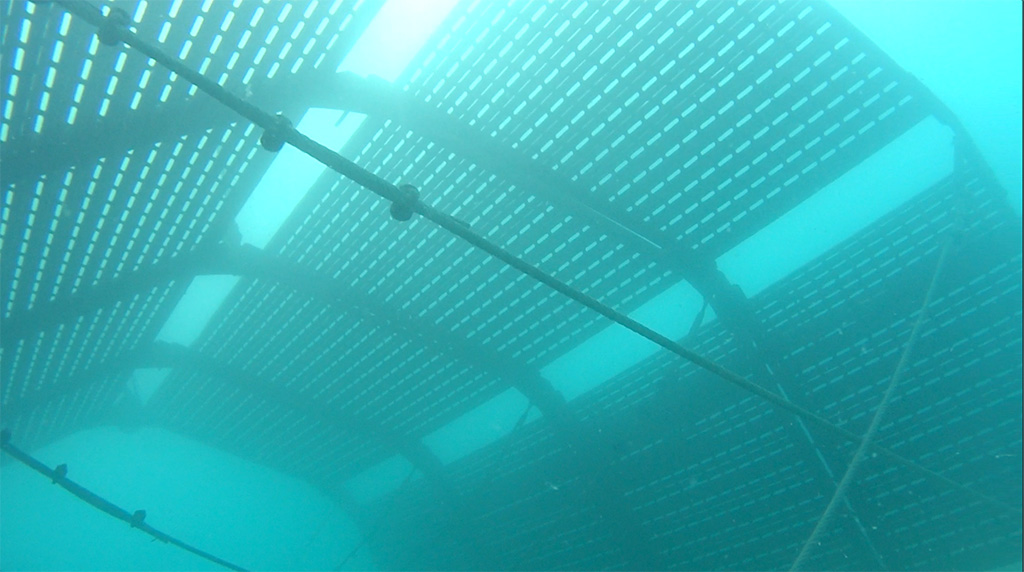

Efficient redundant structures with the highest known strength to weight ratio.

Real time data insight for nearshore marine operations.

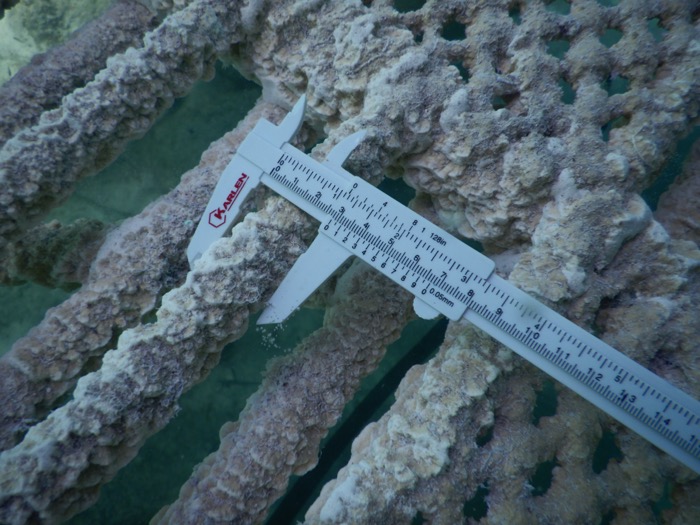

Exploring the novel use of materials alongside electrochemistry to deliver carbon neutral and sustainable living reefs.

Developing hyperboloid reef structures with extraordinary strength-to-weight ratios and intricate internal complexity to dampen wave and develop marine habitats.

Modelling the intricate interaction between ocean waves, currents and reefs structures, to ensure we deliver predictable results at each site.

mm/month of limestone rock

growth rate of calcareous organisms

reduction in CO2

wave energy attenuation

of marine life in reefs

bio-compatable